IEC 62061 – Functional Safety for Machinery Systems

The Essential Guide to Requirements Management and Traceability

Chapters

- 1. Requirements Management

- Overview

- 1 What is Requirements Management?

- 2 Why do you need Requirements Management?

- 3 Four Stages of Requirements Management Processes

- 4 Adopting an Agile Approach to Requirements Management

- 5 Status Request Changes

- 6 Conquering the 5 Biggest Challenges of Requirements Management

- 7 Three Reasons You Need a Requirements Management Solution

- 8 Guide to Poor Requirements: Identify Causes, Repercussions, and How to Fix Them

- 2. Writing Requirements

- Overview

- 1 Functional requirements examples and templates

- 2 Identifying and Measuring Requirements Quality

- 3 How to write system requirement specification (SRS) documents

- 4 The Fundamentals of Business Requirements: Examples of Business Requirements and the Importance of Excellence

- 5 Adopting the EARS Notation to Improve Requirements Engineering

- 6 Jama Connect Advisor™

- 7 Frequently Asked Questions about the EARS Notation and Jama Connect Advisor™

- 8 How to Write an Effective Product Requirements Document (PRD)

- 9 Functional vs. Non-Functional Requirements

- 10 What Are Nonfunctional Requirements and How Do They Impact Product Development?

- 11 Characteristics of Effective Software Requirements and Software Requirements Specifications (SRS)

- 12 8 Do’s and Don’ts for Writing Requirements

- 3. Requirements Gathering and Management Processes

- Overview

- 1 Requirements Engineering

- 2 Requirements Analysis

- 3 A Guide to Requirements Elicitation for Product Teams

- 4 Requirements Gathering Techniques for Agile Product Teams

- 5 What is Requirements Gathering in Software Engineering?

- 6 Defining and Implementing a Requirements Baseline

- 7 Managing Project Scope — Why It Matters and Best Practices

- 8 How Long Do Requirements Take?

- 9 How to Reuse Requirements Across Multiple Products

- 4. Requirements Traceability

- Overview

- 1 How is Traceability Achieved? A Practical Guide for Engineers

- 2 What is Requirements Traceability? Importance Explained

- 3 Tracing Your Way to Success: The Crucial Role of Traceability in Modern Product and Systems Development

- 4 Change Impact Analysis (CIA): A Short Guide for Effective Implementation

- 5 What is Meant by Version Control?

- 6 What is Requirements Traceability and Why Does It Matter for Product Teams?

- 7 Key Traceability Challenges and Tips for Ensuring Accountability and Efficiency

- 8 The Role of a Data Thread in Product and Software Development

- 9 Unraveling the Digital Thread: Enhancing Connectivity and Efficiency

- 10 Requirements Traceability Matrix (RTM): Definition and Purpose

- 11 How to Create and Use a Requirements Traceability Matrix (RTM)

- 12 Traceability Matrix 101: Why It’s Not the Ultimate Solution for Managing Requirements

- 13 Live Traceability vs. After-the-Fact Traceability

- 14 Overcoming Barriers to Live Requirements Traceability™

- 15 Requirements Traceability, What Are You Missing?

- 16 Four Best Practices for Requirements Traceability

- 17 Requirements Traceability: Links in the Chain

- 18 What Are the Benefits of End-to-End Traceability During Product Development?

- 19 FAQs About Requirements Traceability

- 5. Requirements Management Tools and Software

- Overview

- 1 Selecting the Right Requirements Management Tools and Software

- 2 Why Investing in Requirements Management Software Makes Business Sense During an Economic Downturn

- 3 Why Word and Excel Alone is Not Enough for Product, Software, and Systems Development

- 4 Application lifecycle management (ALM)

- 5 Is There Life After DOORS®?

- 6 Can You Track Requirements in Jira?

- 7 Checklist: Selecting a Requirements Management Tool

- 6. Requirements Validation and Verification

- 7. Meeting Regulatory Compliance and Industry Standards

- Overview

- 1 Understanding ISO Standards

- 2 Understanding ISO/IEC 27001: A Guide to Information Security Management

- 3 What is DevSecOps? A Guide to Building Secure Software

- 4 Compliance Management

- 5 What is FMEA? Failure Modes and Effects Analysis

- 6 TÜV SÜD: Ensuring Safety, Quality, and Sustainability Worldwide

- 8. Systems Engineering

- Overview

- 1 What is Systems Engineering?

- 2 How Do Engineers Collaborate? A Guide to Streamlined Teamwork and Innovation

- 3 The Systems Engineering Body of Knowledge (SEBoK)

- 4 What is MBSE? Model-Based Systems Engineering Explained

- 5 Digital Engineering Between Government and Contractors

- 6 Digital Engineering Tools: The Key to Driving Innovation and Efficiency in Complex Systems

- 9. Automotive Development

- 10. Medical Device & Life Sciences Development

- Overview

- 1 The Importance of Benefit-Risk Analysis in Medical Device Development

- 2 Software as a Medical Device: Revolutionizing Healthcare

- 3 What’s a Design History File, and How Are DHFs Used by Product Teams?

- 4 Navigating the Risks of Software of Unknown Pedigree (SOUP) in the Medical Device & Life Sciences Industry

- 5 What is ISO 13485? Your Comprehensive Guide to Compliant Medical Device Manufacturing

- 6 What You Need to Know: ANSI/AAMI SW96:2023 — Medical Device Security

- 7 ISO 13485 vs ISO 9001: Understanding the Differences and Synergies

- 8 Failure Modes, Effects, and Diagnostic Analysis (FMEDA) for Medical Devices: What You Need to Know

- 9 Embracing the Future of Healthcare: Exploring the Internet of Medical Things (IoMT)

- 11. Aerospace & Defense Development

- 12. Architecture, Engineering, and Construction (AEC industry) Development

- 13. Industrial Manufacturing & Machinery, Automation & Robotics, Consumer Electronics, and Energy

- 14. Semiconductor Development

- 15. AI in Product Development

- Glossary

Chapter 13: IEC 62061 – Functional Safety for Machinery Systems

Chapters

- 1. Requirements Management

- Overview

- 1 What is Requirements Management?

- 2 Why do you need Requirements Management?

- 3 Four Stages of Requirements Management Processes

- 4 Adopting an Agile Approach to Requirements Management

- 5 Status Request Changes

- 6 Conquering the 5 Biggest Challenges of Requirements Management

- 7 Three Reasons You Need a Requirements Management Solution

- 8 Guide to Poor Requirements: Identify Causes, Repercussions, and How to Fix Them

- 2. Writing Requirements

- Overview

- 1 Functional requirements examples and templates

- 2 Identifying and Measuring Requirements Quality

- 3 How to write system requirement specification (SRS) documents

- 4 The Fundamentals of Business Requirements: Examples of Business Requirements and the Importance of Excellence

- 5 Adopting the EARS Notation to Improve Requirements Engineering

- 6 Jama Connect Advisor™

- 7 Frequently Asked Questions about the EARS Notation and Jama Connect Advisor™

- 8 How to Write an Effective Product Requirements Document (PRD)

- 9 Functional vs. Non-Functional Requirements

- 10 What Are Nonfunctional Requirements and How Do They Impact Product Development?

- 11 Characteristics of Effective Software Requirements and Software Requirements Specifications (SRS)

- 12 8 Do’s and Don’ts for Writing Requirements

- 3. Requirements Gathering and Management Processes

- Overview

- 1 Requirements Engineering

- 2 Requirements Analysis

- 3 A Guide to Requirements Elicitation for Product Teams

- 4 Requirements Gathering Techniques for Agile Product Teams

- 5 What is Requirements Gathering in Software Engineering?

- 6 Defining and Implementing a Requirements Baseline

- 7 Managing Project Scope — Why It Matters and Best Practices

- 8 How Long Do Requirements Take?

- 9 How to Reuse Requirements Across Multiple Products

- 4. Requirements Traceability

- Overview

- 1 How is Traceability Achieved? A Practical Guide for Engineers

- 2 What is Requirements Traceability? Importance Explained

- 3 Tracing Your Way to Success: The Crucial Role of Traceability in Modern Product and Systems Development

- 4 Change Impact Analysis (CIA): A Short Guide for Effective Implementation

- 5 What is Meant by Version Control?

- 6 What is Requirements Traceability and Why Does It Matter for Product Teams?

- 7 Key Traceability Challenges and Tips for Ensuring Accountability and Efficiency

- 8 The Role of a Data Thread in Product and Software Development

- 9 Unraveling the Digital Thread: Enhancing Connectivity and Efficiency

- 10 Requirements Traceability Matrix (RTM): Definition and Purpose

- 11 How to Create and Use a Requirements Traceability Matrix (RTM)

- 12 Traceability Matrix 101: Why It’s Not the Ultimate Solution for Managing Requirements

- 13 Live Traceability vs. After-the-Fact Traceability

- 14 Overcoming Barriers to Live Requirements Traceability™

- 15 Requirements Traceability, What Are You Missing?

- 16 Four Best Practices for Requirements Traceability

- 17 Requirements Traceability: Links in the Chain

- 18 What Are the Benefits of End-to-End Traceability During Product Development?

- 19 FAQs About Requirements Traceability

- 5. Requirements Management Tools and Software

- Overview

- 1 Selecting the Right Requirements Management Tools and Software

- 2 Why Investing in Requirements Management Software Makes Business Sense During an Economic Downturn

- 3 Why Word and Excel Alone is Not Enough for Product, Software, and Systems Development

- 4 Application lifecycle management (ALM)

- 5 Is There Life After DOORS®?

- 6 Can You Track Requirements in Jira?

- 7 Checklist: Selecting a Requirements Management Tool

- 6. Requirements Validation and Verification

- 7. Meeting Regulatory Compliance and Industry Standards

- Overview

- 1 Understanding ISO Standards

- 2 Understanding ISO/IEC 27001: A Guide to Information Security Management

- 3 What is DevSecOps? A Guide to Building Secure Software

- 4 Compliance Management

- 5 What is FMEA? Failure Modes and Effects Analysis

- 6 TÜV SÜD: Ensuring Safety, Quality, and Sustainability Worldwide

- 8. Systems Engineering

- Overview

- 1 What is Systems Engineering?

- 2 How Do Engineers Collaborate? A Guide to Streamlined Teamwork and Innovation

- 3 The Systems Engineering Body of Knowledge (SEBoK)

- 4 What is MBSE? Model-Based Systems Engineering Explained

- 5 Digital Engineering Between Government and Contractors

- 6 Digital Engineering Tools: The Key to Driving Innovation and Efficiency in Complex Systems

- 9. Automotive Development

- 10. Medical Device & Life Sciences Development

- Overview

- 1 The Importance of Benefit-Risk Analysis in Medical Device Development

- 2 Software as a Medical Device: Revolutionizing Healthcare

- 3 What’s a Design History File, and How Are DHFs Used by Product Teams?

- 4 Navigating the Risks of Software of Unknown Pedigree (SOUP) in the Medical Device & Life Sciences Industry

- 5 What is ISO 13485? Your Comprehensive Guide to Compliant Medical Device Manufacturing

- 6 What You Need to Know: ANSI/AAMI SW96:2023 — Medical Device Security

- 7 ISO 13485 vs ISO 9001: Understanding the Differences and Synergies

- 8 Failure Modes, Effects, and Diagnostic Analysis (FMEDA) for Medical Devices: What You Need to Know

- 9 Embracing the Future of Healthcare: Exploring the Internet of Medical Things (IoMT)

- 11. Aerospace & Defense Development

- 12. Architecture, Engineering, and Construction (AEC industry) Development

- 13. Industrial Manufacturing & Machinery, Automation & Robotics, Consumer Electronics, and Energy

- 14. Semiconductor Development

- 15. AI in Product Development

- Glossary

IEC 62061 – Functional Safety for Machinery Systems

What Is IEC 62061?

IEC 62061 builds on the foundational standards IEC 61508 and ISO 13849 to offer a structured approach to achieving functional safety in machinery systems. It provides a detailed methodology for assessing risks, establishing safety requirements, and validating safety-related control systems. By addressing the entire safety lifecycle, IEC 62061 enables manufacturers to design, implement, and maintain safety systems that align with modern operational and compliance goals.

Integrating Safety Into Machinery Systems

Adopting IEC 62061 offers manufacturers a roadmap for enhancing the safety and reliability of their machinery systems. Key aspects of integration include:

- Seamless Transition Between PL and SIL Frameworks: IEC 62061 bridges the gap between Performance Level (PL) metrics, commonly used in ISO 13849, and Safety Integrity Level (SIL) frameworks, derived from IEC 61508. This flexibility ensures consistency in safety measures across diverse systems and industries.

- Comprehensive Safety Lifecycle Planning: By following IEC 62061’s guidelines, manufacturers can develop robust safety lifecycle plans that integrate risk assessment, system design, validation, and ongoing monitoring. This structured approach ensures that safety is embedded in every stage of machinery operation.

- Optimized Machinery Design: Incorporating IEC 62061 enables manufacturers to design machinery systems that prioritize both safety and operational efficiency. The standard’s emphasis on systematic analysis and testing ensures reliable performance under varied conditions.

Key Benefits of IEC 62061

IEC 62061 stands out for its adaptability, making it applicable to a wide range of machinery systems and industries. Some of its notable benefits include:

- Enhanced Flexibility: The standard allows manufacturers to tailor its principles to meet specific operational and industry requirements. For instance, in semiconductor manufacturing, IEC 62061 helps ensure that high-precision equipment operates reliably under stringent safety protocols.

- Improved Risk Management: With a focus on identifying and mitigating potential hazards, IEC 62061 enhances risk management processes. It equips manufacturers with tools to evaluate risks comprehensively and implement targeted safety measures.

- Compliance and Market Access: Adhering to IEC 62061 simplifies compliance with international safety regulations, enabling manufacturers to access global markets with confidence.

- Lifecycle Efficiency: By integrating safety principles from the design phase through to operation and decommissioning, IEC 62061 reduces lifecycle costs while maintaining high safety standards.

RELATED ARTICLE: Jama Connect® for Robotics Datasheet

Ready to Find Out More?

Our team of experts is here to answer any questions and learn how we can help enable your continued success. Get started with a free 30-day trial, or book a demo!

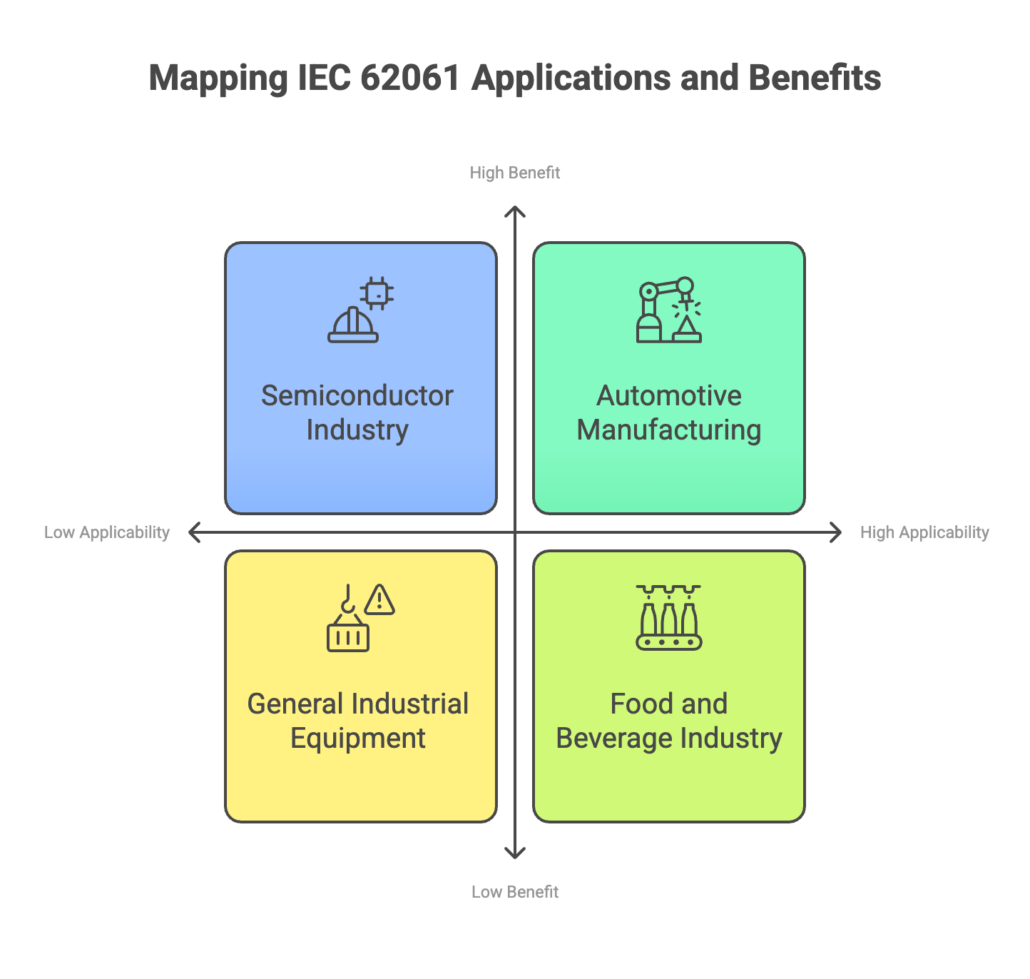

Practical Applications of IEC 62061

IEC 62061’s structured approach makes it particularly valuable in complex and high-risk environments. Examples of its practical applications include:

- Automotive Manufacturing: Ensuring that robotic assembly lines meet stringent safety requirements while maintaining productivity. Automated welding, painting, and assembly robots can be safely integrated into production lines using IEC 62061’s principles, reducing downtime and preventing accidents.

- Semiconductor Industry: Facilitating the safe operation of precision machinery critical to chip manufacturing processes. IEC 62061 helps ensure that equipment such as lithography machines and wafer handlers function reliably while protecting workers and maintaining strict process controls.

- Industrial Equipment: Supporting the development of compliant and reliable machinery for use in factories and processing plants. This includes machinery like conveyors, mixers, and packaging systems, where operational safety and compliance are critical to avoiding production disruptions.

- Energy Sector: Enhancing safety in machinery used for power generation, including turbines, compressors, and control systems. IEC 62061 ensures that these systems operate under stringent safety conditions to minimize risks in hazardous environments.

- Food and Beverage Industry: Promoting safety in high-speed processing and packaging equipment. By applying IEC 62061, manufacturers can ensure that machinery operates efficiently while safeguarding operators from potential hazards such as sharp tools and high temperatures.

- Pharmaceutical Manufacturing: Ensuring that machinery used for production, filling, and sealing processes adheres to strict safety and cleanliness standards. IEC 62061 supports the design of systems that meet regulatory requirements while protecting both operators and products.

RELATED ARTICLE: Loram Rides the Fast Track to Software Safety with Jama Connect®

Conclusion

IEC 62061 provides a robust framework for achieving functional safety in machinery systems, building on the strengths of IEC 61508 and ISO 13849. Its adaptable and comprehensive approach empowers manufacturers to design and operate safer, more efficient machinery. By integrating risk assessment, lifecycle planning, and validation, IEC 62061 not only enhances safety but also optimizes operational performance and compliance.

Note: This article was drafted with the aid of AI. Additional content, edits for accuracy, and industry expertise by Kenzie Ingram and Andrei Rizescu.

In this Video, Learn About the Top Challenges in ICE

IEC 62061 builds on the foundational standards IEC 61508 and ISO 13849 to offer a structured approach to achieving functional safety in machinery systems. It provides a detailed methodology for assessing risks, establishing safety requirements, and validating safety-related control systems

Book a Demo

See Jama Connect in Action!

Our Jama Connect experts are ready to guide you through a personalized demo, answer your questions, and show you how Jama Connect can help you identify risks, improve cross-team collaboration, and drive faster time to market.