Jama Software® Announces Largest Scale Achieved by Any Requirements Management Software

Jama Connect® 9.5 proven to scale to at least 10 million requirements in a single project to handle the largest product, systems, and software development efforts.

Jama Software®, the industry-leading requirements management and traceability solution provider, has announced that Jama Connect® has set yet another scalability record with over 10 million requirements managed in a single project (within a standard cloud instance) with P75 user interface load times under three (3) seconds. 10 million requirements per project represents a new benchmark in the industry, clearly showing that Jama Connect is able to meet both the current and future scalability needs of our customers. It is also important to note that no project data storage limits were hit during this boundary condition test, so the actual limit has not yet been reached.

Engineering organizations are looking for software partners that can handle large-scale, collaborative projects that span engineering disciplines, customers, and suppliers. This performance benchmark demonstrates Jama Connect’s unique ability to handle the scale required within a single project. Today, our customers work with tens of millions of requirements across projects in a single instance of Jama Connect. This latest single project scalability milestone adds to Jama Connect’s market-leading standing for security, scalability, and performance in the cloud including:

- Over 100,000 trailing 90-day active users

- Daily users spanning 82 countries

- 16ms First Input Delay (FID) response times

- P75 response times of 2.7 seconds

- The only requirements management application that is SOC 2 Type 2 certified at the environment AND application layers

- The richest REST API with over 200 separate API functions

- Over 600 million API cloud service requests per month

“Jama Software continues to lead the market in performance, security, and usability at scale,” said Josh Turpen, Chief Product Officer at Jama Software. “We are pushing beyond the 10 million threshold and will continue to deliver unmatched cloud capabilities to our customers.”

Related: Getting Started with Jama Connect REST API

About Jama Software

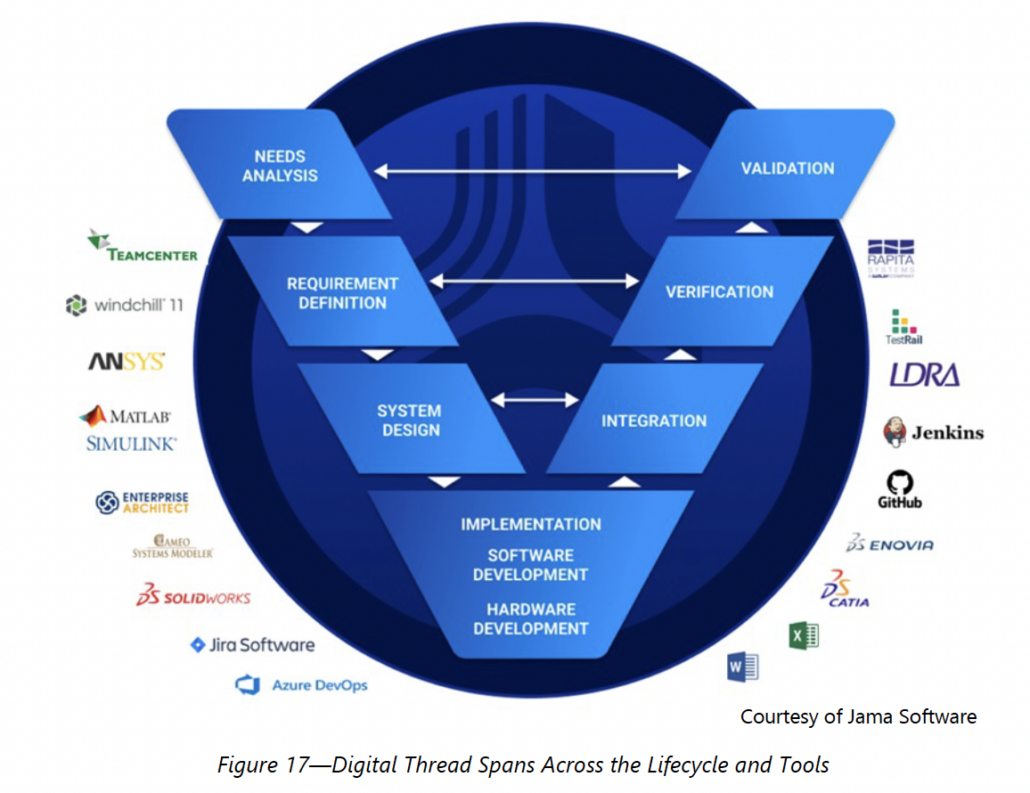

Jama Software® is focused on maximizing innovation success in multidisciplinary engineering organizations. Numerous firsts for humanity in fields such as fuel cells, electrification, space, software-defined vehicles, surgical robotics, and more all rely on Jama Connect® requirements management software to minimize the risk of defects, rework, cost overruns, and recalls. Using Jama Connect, engineering organizations can now intelligently manage the development process by leveraging Live Traceability™ across best-of-breed tools to measurably improve outcomes. Our rapidly growing customer base spans the automotive, medical device, life sciences, semiconductor, aerospace & defense, industrial manufacturing, consumer electronics, financial services, and insurance industries.

For more information about Jama Connect services, please visit www.jamasoftware.com

Read the official press release here:

Jama Software® Announces Largest Scale Achieved by Any Requirements Management Software