![[Webinar Recap] Elevating Your Medical Device and Life Sciences Product Development Processes with Jama Connect® [Webinar Recap] Elevating Your Medical Device and Life Sciences Product Development Processes with Jama Connect®](https://www.jamasoftware.com/media/2023/07/2023-Webinar-Recap-Med-Update.png)

In this blog, we provide a preview of the “Elevating Your Medical Device and Life Sciences Product Development Processes with Jama Connect®” webinar.

Curious to learn how the Medical Device Framework in Jama Connect® can help streamline your compliance efforts and ensure your products meet necessary regulatory requirements?

During this informative session, Vincent Balgos, Director of Medical Device Solutions at Jama Software® discusses the latest solution offerings for Medical Device and Life Sciences in Jama Connect, including:

- Updated Software as Medical Device (SaMD) framework incorporating readily available off-the-shelf elements for workflow and efficiency

- Newly developed Research Use Only (RUO) and In-Vitro Diagnostics (IVD) frameworks

- Refined solution enhancements, including new and updated report templates

- Self-guided onboarding framework to assist new users in Jama Connect

Discover how Jama Connect can help you optimize compliance and regulatory processes, helping you stay ahead in the constantly evolving medical device industry.

Below is an abbreviated transcript and a recording of our webinar.

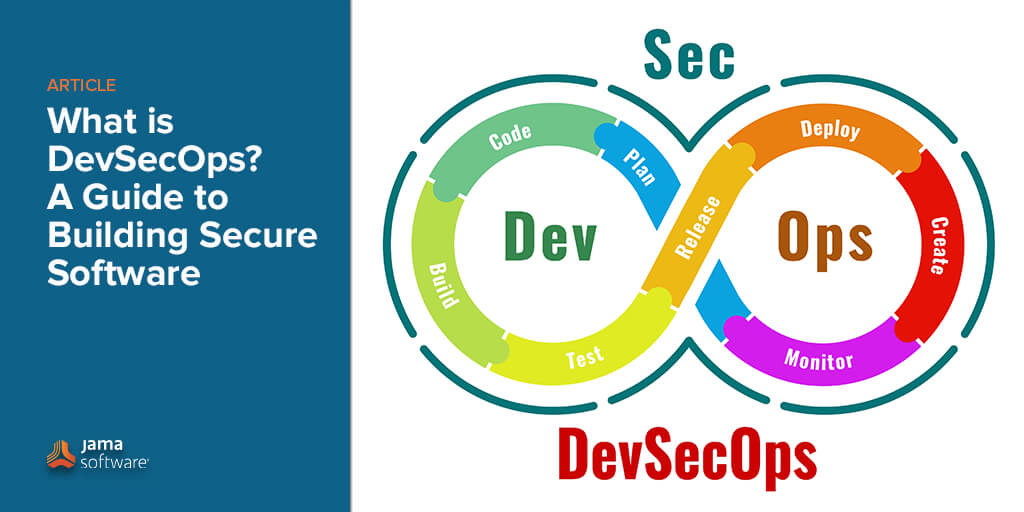

Elevating Your Medical Device and Life Sciences Product Development Processes with Jama Connect®

Vincent Balgos: For today’s webinar, I’d like to talk about our updates to our Medical Device and Life Sciences Solution 2.0. For the agenda, there are quite a few improvements I’d like to share with you today. The first one is really just kind of talking about general overview and general improvements in terms of risk, some new features that we’ve enabled with Jama Connect, but also some new and updated solutions such as Software as a Medical Device, Research Use Only, and our new self-guided onboarding framework.

So the intent of the update is to continually improve Jama solution to the medical device and life sciences industries based on a variety of factors, including new Jama Connect features and abilities that help streamline general product development processes and industry best practices. Also adapts to the ever-evolving regulations such as MDR, IVDR, and potential changes to the lab developed test area. We’ll talk about more of this in the ROU space. We’ve also included internal research and internal experience with over 80 years of industry experience from the internal Jama team. And lastly, we’ve also incorporated some feedback from customers like yourselves on best practices, innovative solutions, and new use cases. So thank you ahead of time and please continue to contribute via the Jama Community Ideation page or discussion with Jama folks.

These solutions that are presented are compatible and available with Jama Connect for both our cloud customers, both the standard and validated, and our self-hosted environments. Some highlighted features may require version updates, and this is really particular to our self-hosted customers with legacy versions.

RELATED: The Top 5 Challenges in Digital Health Solution Development

Balgos: So what I’d like to first talk about is the general organization and layout. So what I’m going to do is come back between screens, between the PowerPoint and the actual, the demo itself.

So the first thing I want to show is the general organization and layout of our new Medical Device Framework 2.0. The first thing I want to show is when we go ahead and take a look, you’ll see here in this new folder we have something enumerated Medical Device Framework 2.0, that actually has our new Medical Device Framework and our other additional popular framework such as SAMD and Consumables Framework.

The other folder to mention is really kind of our new use case library that highlights additional use cases that we’ve seen across our 300 plus customers and their practices using Jama Connect. We’ll deep dive into each one of these very shortly. We’ve also archived the current… sorry, the previous Medical Device Framework 1.0 for your reference only.

So now let’s go ahead and dive into the overview of the MDF 2.0. So I’m going to jump into the tool. And as you can see here right on the screen, we’ve updated the relationship rule diagram with some minor improvements. The first thing we’ve done is really streamline the risk stream where we remove the validation trace and trace this now to an external resource item type. The purpose of this item type is a general documentation catch call for a lot of various traces that you may have. The most common example is associated with risk. So as many of you may know, not all risk controls are requirements. So we still need a way to trace to these non-requirement risk controls. These controls could be IFUs or instructions for use, training, labeling, or labeling and packaging, et cetera, and may vary depending on your risk management procedures. This provides additional risk coverage traceability that provides flexibility for your organization.

RELATED: Jama Connect® for Digital Health Solution Overview

Balgos: Another thing that we’ve done is actually updated our hazards library to include general hazards identified in 14971. As you can see here on the screen, we’ve now populated the general hazards identified in 14971 based on the information that you have. So you have pretty much a starting place with your hazard library that you have here.

The next item that I’d like to talk about is actually this new feature called the Risk Lookup Matrix. Available in 8.754, this features allows a new lookup matrix risk analysis approach that automatically outputs the desired content based on a pre-configured lookup table. This really aligns with 14971. Let me show you a quick demo of this because we’ve now implemented this as part of our Medical Device Framework 2.0.

RELATED: The Importance of Benefit-Risk Analysis in Medical Device Development

Balgos: As you can see here on the screen, I have a new item type called Risk Evaluation 2.0 that kind of, again, follows the general 14971 schema of hazardous sequence of events, hazardous situations harmed. But here is now where we’ve implemented this new lookup matrix feature where now I’ve now identified the input pick lists where I may be able to change this, and then that automatically updates my risk level based off that matrix. So for example here, if I went ahead and increases the frequency and I increase my severity from here over here, and this one as well, I can see that both my P total and risk analysis has been updated per the lookup matrix. We have an additional features [inaudible 00:07:27] video that showcases a little bit more. So we definitely encourage you to look at that further.

The other thing that we wanted to share with particularly this medical device update is we have now included pre-configured FMEA item types for ease of implementation for your risk processes. If I go ahead and look into my admin area, what I mean by this is when I look at my item type, I’ve now included pre-configured DFMEAs, process FMEAs, and use FMEAs that you may configure based on your organization. This just allows for streamlining of your risk measures processing quickly to Jama Connect.

To watch the entire webinar, visit

Elevating Your Medical Device and Life Sciences Product Development Processes with Jama Connect®

![[Webinar Recap] New Research Findings: The Impact of Live Traceability™ on the Digital Thread [Webinar Recap] New Research Findings: The Impact of Live Traceability™ on the Digital Thread](https://www.jamasoftware.com/media/2023/06/Copy-of-2023-Product-Development-Complexities_Social-Image-1.png)

![[Webinar Recap] An Overview of the EU Medical Device Regulation (MDR) and In-Vitro Device Regulation (IVDR) [Webinar Recap] An Overview of the EU Medical Device Regulation (MDR) and In-Vitro Device Regulation (IVDR)](https://www.jamasoftware.com/media/2023/04/BLOG-RECAP-Medical-Device-Webinar-Social-Image.png)