Unraveling the Digital Thread: Enhancing Connectivity and Efficiency

The Essential Guide to Requirements Management and Traceability

Chapters

- 1. Requirements Management

- Overview

- 1 What is Requirements Management?

- 2 Why do you need Requirements Management?

- 3 Four Stages of Requirements Management Processes

- 4 Adopting an Agile Approach to Requirements Management

- 5 Status Request Changes

- 6 Conquering the 5 Biggest Challenges of Requirements Management

- 7 Three Reasons You Need a Requirements Management Solution

- 8 Guide to Poor Requirements: Identify Causes, Repercussions, and How to Fix Them

- 2. Writing Requirements

- Overview

- 1 Functional requirements examples and templates

- 2 Identifying and Measuring Requirements Quality

- 3 How to write system requirement specification (SRS) documents

- 4 The Fundamentals of Business Requirements: Examples of Business Requirements and the Importance of Excellence

- 5 Adopting the EARS Notation to Improve Requirements Engineering

- 6 Jama Connect Advisor™

- 7 Frequently Asked Questions about the EARS Notation and Jama Connect Advisor™

- 8 How to Write an Effective Product Requirements Document (PRD)

- 9 Functional vs. Non-Functional Requirements

- 10 What Are Nonfunctional Requirements and How Do They Impact Product Development?

- 11 Characteristics of Effective Software Requirements and Software Requirements Specifications (SRS)

- 12 8 Do’s and Don’ts for Writing Requirements

- 3. Requirements Gathering and Management Processes

- Overview

- 1 Requirements Engineering

- 2 Requirements Analysis

- 3 A Guide to Requirements Elicitation for Product Teams

- 4 Requirements Gathering Techniques for Agile Product Teams

- 5 What is Requirements Gathering?

- 6 Defining and Implementing a Requirements Baseline

- 7 Managing Project Scope — Why It Matters and Best Practices

- 8 How Long Do Requirements Take?

- 9 How to Reuse Requirements Across Multiple Products

- 4. Requirements Traceability

- Overview

- 1 What is Requirements Traceability? Importance Explained

- 2 How is Traceability Achieved? A Practical Guide for Engineers

- 3 Tracing Your Way to Success: The Crucial Role of Traceability in Modern Product and Systems Development

- 4 Change Impact Analysis (CIA): A Short Guide for Effective Implementation

- 5 What is Requirements Traceability and Why Does It Matter for Product Teams?

- 6 What is Meant by Version Control?

- 7 Key Traceability Challenges and Tips for Ensuring Accountability and Efficiency

- 8 Unraveling the Digital Thread: Enhancing Connectivity and Efficiency

- 9 The Role of a Data Thread in Product and Software Development

- 10 How to Create and Use a Requirements Traceability Matrix

- 11 Traceability Matrix 101: Why It’s Not the Ultimate Solution for Managing Requirements

- 12 Live Traceability vs. After-the-Fact Traceability

- 13 Overcoming Barriers to Live Requirements Traceability™

- 14 Requirements Traceability, What Are You Missing?

- 15 Four Best Practices for Requirements Traceability

- 16 Requirements Traceability: Links in the Chain

- 17 What Are the Benefits of End-to-End Traceability During Product Development?

- 5. Requirements Management Tools and Software

- Overview

- 1 Selecting the Right Requirements Management Tools and Software

- 2 Why Investing in Requirements Management Software Makes Business Sense During an Economic Downturn

- 3 Why Word and Excel Alone is Not Enough for Product, Software, and Systems Development

- 4 Application lifecycle management (ALM)

- 5 Is There Life After DOORS®?

- 6 Can You Track Requirements in Jira?

- 7 Checklist: Selecting a Requirements Management Tool

- 6. Requirements Validation and Verification

- 7. Meeting Regulatory Compliance and Industry Standards

- Overview

- 1 Understanding ISO Standards

- 2 Understanding ISO/IEC 27001: A Guide to Information Security Management

- 3 What is DevSecOps? A Guide to Building Secure Software

- 4 Compliance Management

- 5 What is FMEA? Failure Modes and Effects Analysis

- 6 TÜV SÜD: Ensuring Safety, Quality, and Sustainability Worldwide

- 8. Systems Engineering

- Overview

- 1 What is Systems Engineering?

- 2 How Do Engineers Collaborate? A Guide to Streamlined Teamwork and Innovation

- 3 The Systems Engineering Body of Knowledge (SEBoK)

- 4 What is MBSE? Model-Based Systems Engineering Explained

- 5 Digital Engineering Between Government and Contractors

- 6 Digital Engineering Tools: The Key to Driving Innovation and Efficiency in Complex Systems

- 9. Automotive Development

- 10. Medical Device & Life Sciences Development

- Overview

- 1 The Importance of Benefit-Risk Analysis in Medical Device Development

- 2 Software as a Medical Device: Revolutionizing Healthcare

- 3 What’s a Design History File, and How Are DHFs Used by Product Teams?

- 4 Navigating the Risks of Software of Unknown Pedigree (SOUP) in the Medical Device & Life Sciences Industry

- 5 What is ISO 13485? Your Comprehensive Guide to Compliant Medical Device Manufacturing

- 6 What You Need to Know: ANSI/AAMI SW96:2023 — Medical Device Security

- 7 ISO 13485 vs ISO 9001: Understanding the Differences and Synergies

- 8 Failure Modes, Effects, and Diagnostic Analysis (FMEDA) for Medical Devices: What You Need to Know

- 9 Embracing the Future of Healthcare: Exploring the Internet of Medical Things (IoMT)

- 11. Aerospace & Defense Development

- 12. Architecture, Engineering, and Construction (AEC industry) Development

- 13. Industrial Manufacturing & Machinery, Automation & Robotics, Consumer Electronics, and Energy

- 14. Semiconductor Development

- 15. AI in Product Development

- Glossary

Chapter 4: Unraveling the Digital Thread: Enhancing Connectivity and Efficiency

Chapters

- 1. Requirements Management

- Overview

- 1 What is Requirements Management?

- 2 Why do you need Requirements Management?

- 3 Four Stages of Requirements Management Processes

- 4 Adopting an Agile Approach to Requirements Management

- 5 Status Request Changes

- 6 Conquering the 5 Biggest Challenges of Requirements Management

- 7 Three Reasons You Need a Requirements Management Solution

- 8 Guide to Poor Requirements: Identify Causes, Repercussions, and How to Fix Them

- 2. Writing Requirements

- Overview

- 1 Functional requirements examples and templates

- 2 Identifying and Measuring Requirements Quality

- 3 How to write system requirement specification (SRS) documents

- 4 The Fundamentals of Business Requirements: Examples of Business Requirements and the Importance of Excellence

- 5 Adopting the EARS Notation to Improve Requirements Engineering

- 6 Jama Connect Advisor™

- 7 Frequently Asked Questions about the EARS Notation and Jama Connect Advisor™

- 8 How to Write an Effective Product Requirements Document (PRD)

- 9 Functional vs. Non-Functional Requirements

- 10 What Are Nonfunctional Requirements and How Do They Impact Product Development?

- 11 Characteristics of Effective Software Requirements and Software Requirements Specifications (SRS)

- 12 8 Do’s and Don’ts for Writing Requirements

- 3. Requirements Gathering and Management Processes

- Overview

- 1 Requirements Engineering

- 2 Requirements Analysis

- 3 A Guide to Requirements Elicitation for Product Teams

- 4 Requirements Gathering Techniques for Agile Product Teams

- 5 What is Requirements Gathering?

- 6 Defining and Implementing a Requirements Baseline

- 7 Managing Project Scope — Why It Matters and Best Practices

- 8 How Long Do Requirements Take?

- 9 How to Reuse Requirements Across Multiple Products

- 4. Requirements Traceability

- Overview

- 1 What is Requirements Traceability? Importance Explained

- 2 How is Traceability Achieved? A Practical Guide for Engineers

- 3 Tracing Your Way to Success: The Crucial Role of Traceability in Modern Product and Systems Development

- 4 Change Impact Analysis (CIA): A Short Guide for Effective Implementation

- 5 What is Requirements Traceability and Why Does It Matter for Product Teams?

- 6 What is Meant by Version Control?

- 7 Key Traceability Challenges and Tips for Ensuring Accountability and Efficiency

- 8 Unraveling the Digital Thread: Enhancing Connectivity and Efficiency

- 9 The Role of a Data Thread in Product and Software Development

- 10 How to Create and Use a Requirements Traceability Matrix

- 11 Traceability Matrix 101: Why It’s Not the Ultimate Solution for Managing Requirements

- 12 Live Traceability vs. After-the-Fact Traceability

- 13 Overcoming Barriers to Live Requirements Traceability™

- 14 Requirements Traceability, What Are You Missing?

- 15 Four Best Practices for Requirements Traceability

- 16 Requirements Traceability: Links in the Chain

- 17 What Are the Benefits of End-to-End Traceability During Product Development?

- 5. Requirements Management Tools and Software

- Overview

- 1 Selecting the Right Requirements Management Tools and Software

- 2 Why Investing in Requirements Management Software Makes Business Sense During an Economic Downturn

- 3 Why Word and Excel Alone is Not Enough for Product, Software, and Systems Development

- 4 Application lifecycle management (ALM)

- 5 Is There Life After DOORS®?

- 6 Can You Track Requirements in Jira?

- 7 Checklist: Selecting a Requirements Management Tool

- 6. Requirements Validation and Verification

- 7. Meeting Regulatory Compliance and Industry Standards

- Overview

- 1 Understanding ISO Standards

- 2 Understanding ISO/IEC 27001: A Guide to Information Security Management

- 3 What is DevSecOps? A Guide to Building Secure Software

- 4 Compliance Management

- 5 What is FMEA? Failure Modes and Effects Analysis

- 6 TÜV SÜD: Ensuring Safety, Quality, and Sustainability Worldwide

- 8. Systems Engineering

- Overview

- 1 What is Systems Engineering?

- 2 How Do Engineers Collaborate? A Guide to Streamlined Teamwork and Innovation

- 3 The Systems Engineering Body of Knowledge (SEBoK)

- 4 What is MBSE? Model-Based Systems Engineering Explained

- 5 Digital Engineering Between Government and Contractors

- 6 Digital Engineering Tools: The Key to Driving Innovation and Efficiency in Complex Systems

- 9. Automotive Development

- 10. Medical Device & Life Sciences Development

- Overview

- 1 The Importance of Benefit-Risk Analysis in Medical Device Development

- 2 Software as a Medical Device: Revolutionizing Healthcare

- 3 What’s a Design History File, and How Are DHFs Used by Product Teams?

- 4 Navigating the Risks of Software of Unknown Pedigree (SOUP) in the Medical Device & Life Sciences Industry

- 5 What is ISO 13485? Your Comprehensive Guide to Compliant Medical Device Manufacturing

- 6 What You Need to Know: ANSI/AAMI SW96:2023 — Medical Device Security

- 7 ISO 13485 vs ISO 9001: Understanding the Differences and Synergies

- 8 Failure Modes, Effects, and Diagnostic Analysis (FMEDA) for Medical Devices: What You Need to Know

- 9 Embracing the Future of Healthcare: Exploring the Internet of Medical Things (IoMT)

- 11. Aerospace & Defense Development

- 12. Architecture, Engineering, and Construction (AEC industry) Development

- 13. Industrial Manufacturing & Machinery, Automation & Robotics, Consumer Electronics, and Energy

- 14. Semiconductor Development

- 15. AI in Product Development

- Glossary

Unraveling the Digital Thread: Enhancing Connectivity and Efficiency

In the fast-changing landscape of the modern digital age, the “digital thread” has emerged as a game changer, especially within the realms of complex industries such as aerospace and defense, medical device, and automotive. This digital thread signifies a continuous and interconnected flow of digital information that traverses the entire lifecycle of a product, project, or process. This chapter of the requirements management guide is an overview of the digital thread, highlighting its significance and how it optimizes operations across many industries and sectors.

According to CIMdata “The concept of a digital thread providing automated linkage of multiple representations of a product, each tuned to the needs of various creators and consumers along the lifecycle, is very powerful.”

Understanding the Essence of the Digital Thread

According to a well-respect paper from MIT titled Engineering with Digital Thread, the definition of the digital thread is “A data-driven architecture that links together information generated from across the product lifecycle and is envisioned to be the primary or authoritative data and communication platform for a company’s products at any instance of time.”

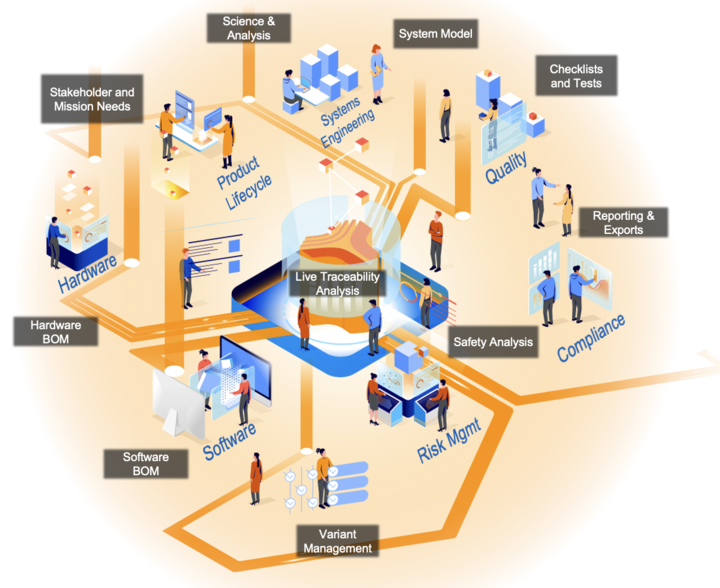

The digital thread is an orchestrated flow of information, ensuring its accessibility and relevance across engineering domains such as hardware, software, manufacturing, operation, and maintenance. The core principle of the digital thread is to give stakeholders the right information, precisely when it is needed, enabling them to make well-informed decisions, ultimately enhancing operational efficiency.

This interconnected information embodies a plethora of critical aspects including: design specifications, manufacturing instructions, testing data, operational performance metrics, maintenance records, and more. The digital thread also ensures that all stakeholders, whatever role they have in the lifecycle, have unfettered access to pertinent and up-to-date information, facilitating a holistic understanding and fostering collaboration.

In a previous blog post, Jama Software’s CEO, Marc Osofsky, spoke about the importance of the digital thread, saying, “The product development process is often fragmented across siloed teams and tools which leads to significant risk of product delays, defects, cost overruns, failed verification and validation, recalls, etc. End-to-end process visibility is required for better cross-team collaboration and the early detection of anomalies to reduce these risks. To solve this, some organizations attempt to force everyone to use single vendor platforms with strong functionality in one area but little to no functionality in another, forgoing their choice of best-of-breed tools. This solution is neither practical — nor particularly realistic — since engineers are (and should continue to be) allowed to choose discipline-specific tooling which optimize their activities.”

The Multifaceted Components of the Digital Thread

1. Concept Design and Development:

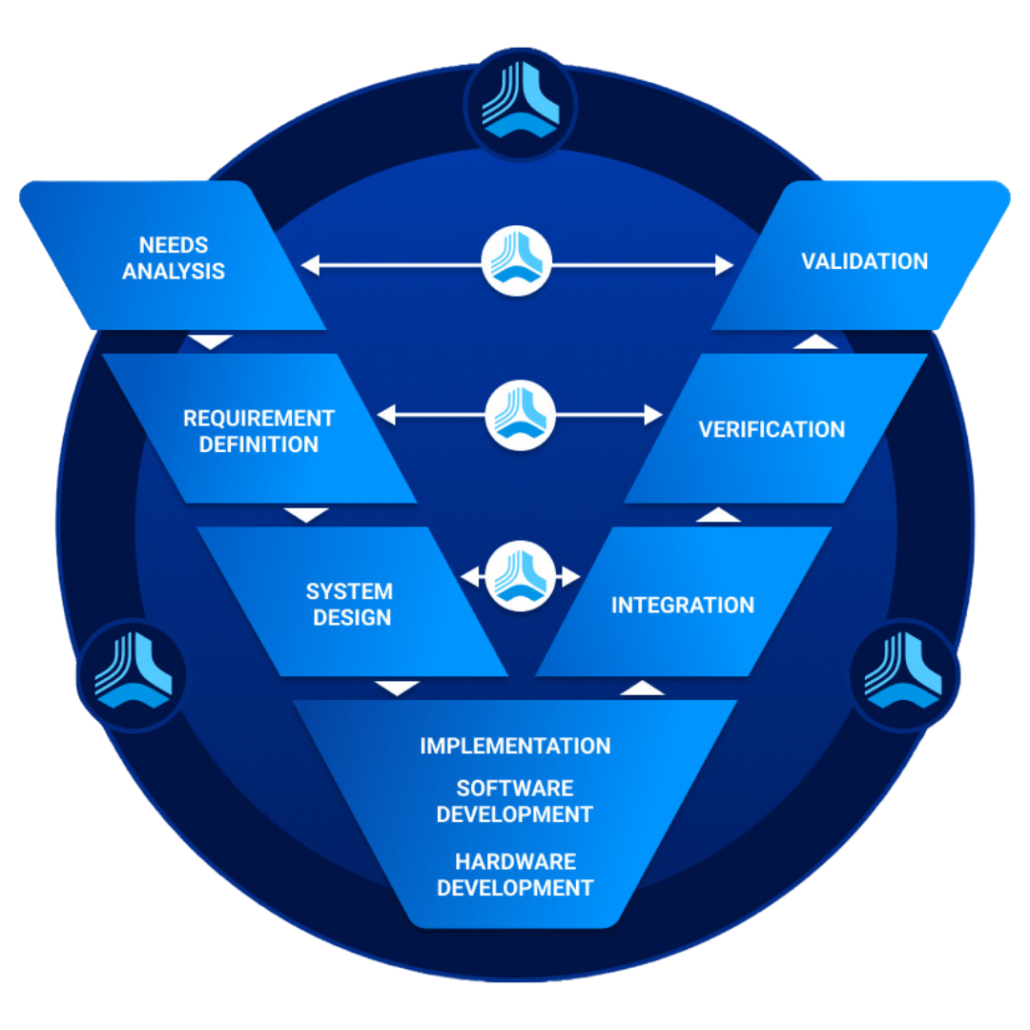

The inception of the digital thread should occur during the early stages of the product lifecycle, specifically within the concept development phase. It encompasses the creation of multiple digital models or representations of the product or process, encompassing design specifications, system architecture, behaviors, requirements, simulations, and an array of associated data.

2. Manufacturing:

As the product transitions into the manufacturing phase, the digital thread seamlessly integrates information pertaining to production processes, quality control measures, assembly instructions, and other critical manufacturing-related data.

3. Operations and Performance Monitoring:

During the operational phase, the digital thread continues to provide valuable insights into real-time performance, usage patterns, and feedback from the field. This facilitates a continuous improvement cycle, enabling organizations to optimize product performance and customer satisfaction.

4. Maintenance and Service:

The digital thread extends into the maintenance and service phase, incorporating crucial data regarding maintenance schedules, service records, spare parts, and repair procedures. This ensures efficient maintenance practices, prolongs the product’s lifecycle, and enhances customer support.

The Inherent Advantages of Embracing the Digital Thread

1. Facilitating Enhanced Collaboration and Communication:

One of the primary advantages of the digital thread is its ability to foster seamless collaboration among stakeholders. By ensuring that everyone has access to the most current and relevant information, it becomes a catalyst for effective decision-making and problem-solving.

2. Optimizing Efficiency and Productivity:

The streamlined flow of information orchestrated by the digital thread significantly enhances operational efficiency. This translates to reduced delays, minimized errors, and optimal resource utilization, ultimately leading to shorter development cycles and reduced time-to-market.

3. Cost Reduction and Resource Optimization:

Real-time data and insights made available through the digital thread aid in identifying areas for cost reduction and resource optimization. This informed decision-making ultimately leads to improved profitability and sustainability.

4. Assuring Quality at Every Phase:

A major advantage of the digital thread is the continuous assurance of quality throughout the entire lifecycle of the product. The availability of accurate and detailed data empowers organizations to enforce rigorous quality control measures, resulting in a higher quality end product.

RELATED ARTICLE: Requirements Traceability Benchmark

Navigating Challenges and Pioneering Solutions

While the promise of the digital thread is profound, its successful implementation does not come without its set of challenges. These hurdles often encompass data interoperability, cybersecurity concerns, and the integration of existing systems. Addressing these challenges necessitates the establishment of robust data standards, the deployment of stringent cybersecurity measures, and a well-thought-out strategic plan for seamless integration.

Conclusion: Embracing the Digital Thread for Future Success

In conclusion, the digital thread epitomizes a critical concept in the contemporary digital era, facilitating a seamless flow of information across the intricate tapestry of a product or process lifecycle. Through enhanced connectivity and optimized efficiency, the digital thread empowers organizations to innovate, improve, and achieve excellence within their respective domains. As industries continue their relentless evolution, embracing and effectively implementing the digital thread will become not only a competitive edge but a necessity for sustainable success and growth. Embracing the digital thread is a step towards a future where connectivity and efficiency reign supreme, setting the stage for a new era of productivity and achievement.

Note: This article was drafted with the aid of AI. Additional content, edits for accuracy, and industry expertise by McKenzie Jonsson and Cary Bryczek.

In This Video, Learn About the Digital Thread in Aerospace and Defense

THE DIGITAL THREAD a data-driven architecture that links together information generated from across the product lifecycle and is envisioned to be the primary or authoritative data and communication platform for a company’s products at any instance of time.

Book a Demo

See Jama Connect in Action!

Our Jama Connect experts are ready to guide you through a personalized demo, answer your questions, and show you how Jama Connect can help you identify risks, improve cross-team collaboration, and drive faster time to market.