Risk management plays a pivotal role in medical device development, helping ensure patient safety and product quality. Risk management is often misunderstood. It’s a process that could be cumbersome for organizations who don’t know where to get started, or worse, start too late in their development process.

After our recent half-day risk management seminar in the Netherlands, we sat down with award-winning medical device risk management educator, author, and consultant Bijan Elahi to hear his thoughts on risk management in medical device development.

Read the full interview below for Elahi’s take on the importance of risk management, best practices, and how use it to gain confidence in your compliance.

Jama Software: Thank you for joining us Bijan. For our readers who may not be familiar with your work, can you tell us a little bit about your background and experience with risk management?

Bijan Elahi: I’ve been doing systems engineering and risk management for the last 30 years, beginning my work in the aerospace industry at various companies, with my last job at NASA. In the early 1990s I was approached by the medical device industry for help with risk management. This was a time when there were no standards for medical device risk management, and medical device companies had no consistent way of doing risk management. I began helping one medical device company, then another, and soon I changed industries altogether, from aerospace to medical technologies.

The first version of ISO 14971 was published in the year 2000, finally providing risk management guidance to the global medical device community. I’ve been helping medtech companies understand that standard and apply it to product development ever since. In the last five or six years, I’ve also started teaching and consulting in risk management more broadly.

Jama Software: Looking back at your work in risk management, can you summarize for us what it is and why it’s so important to medical device development?

Bijan Elahi: Risk management, in a nutshell, is the process of identifying hazards, estimating the risks, controlling the risks, and then monitoring and reporting how you did. But once you identify the hazards, you also need to know why they happened, what are the causes of those hazards, and then what you can do to minimize the risk of harm from those hazards. Risk management is both an art and a science. It is not like mathematics that is perfectly clear. There are a lot of grey areas in risk management that require sound judgement and both a creative and a scientific approach.

Risk management is important because you can’t commercialize a medical product without it. It’s legally required to perform risk management before you can get approval to sell your product globally. Second, it helps you make safer products. We have a moral obligation to our patients to make the safest possible products for them.

It’s also important for business and financial reasons. Poor risk management can be expensive and often results in recall costs and even punitive damages. If you make safe products then you’ll have a better reputation, and you can sell more. In addition, it helps save money in product development, because risk management allows for the early identification of design weaknesses and allows targeted allocation of limited engineering resources with priority to the safety critical areas.

Jama Software: What are some risk management best practices product developers should consider as they’re moving through the development cycle?

Bijan Elahi: One of the things that medical device developers should recognize is that risk management should be done as early as possible. Even as early as the concept stage. Another thing is having a robust process for risk management that is both compliant and efficient. You can get really complex with risk management. So, avoid overcomplexity and have a process that is both understandable and explainable. Understandable to your own staff and also to regulatory bodies. When you have a regulatory auditor or reviewer asking questions about your risk management process, if you can’t help them understand, your process isn’t working. Because ultimately, you need to persuade a regulatory authority to approve your product.

Read our eBook to learn more about risk management for Class II and Class III medical device development.

Jama Software: You spoke in your presentation about an old vs. new way of thinking about risk management, can you expand on what you meant for our readers?

Bijan Elahi: The old way of thinking was where product developers saw risk management as a necessary evil. They would be focused on the design of the product and making it work. And then when they finished the design, they would say, “Well, if we’re going to commercialize this product, we need to show that we did risk management, and find somebody to do a retrospective analysis and write a report that this product is adequately safe.” That’s old thinking. The new way of thinking is to consider risk management as a value-added activity and a partner with product design. Risk management and product design should work together in lockstep. This way, we get real value from risk management.

In fact, regulatory bodies today expect this new way of doing the work. They don’t want to see that you didn’t do any risk management during the development process and that at the end you just wrote a report to retrospectively cover your bases. This way of thinking is not only bad for your company, it’s also bad for the consumer and bad for the product. A lot of times if you have finished your design, and then suddenly you make a discovery of a safety hazard, it may be too late to fix it or maybe just too expensive. Some companies would just try to somehow get the product out anyway, which is bad for everybody and doesn’t really save you any money.

Jama Software: Let’s talk a little bit about the latest version of ISO 14971 that was released at the end of last year. Have you had a chance to review the latest 2019 version and are there any new changes developers should be aware of?

Bijan Elahi: Yes, I have. ISO 14971 is the international standard for medical device risk management, and it is recognized by most countries. It is a very important standard because conformance to it is the easiest way to establish the safety of your medical device and to persuade a regulatory body to approve your device. The 2019 version has some changes in it, but they are not so extensive that they would overburden the manufacturers. There are some new definitions and some changes to existing definitions.

Also, there are some new concepts that are introduced. For example, in the 2012 version, the requirement was to reduce the risks “as far as possible.” In 2019, a new concept is introduced to reduce the risks to “as low as reasonably achievable.” And then in the previous version, 2007, there was another concept called “as low as reasonably practicable.” So, there are now three concepts in the most recent version about how can you strategize about reducing risks.

Jama Software: Speaking of changing industry regulations, one topic that’s been top of mind for medical device developers in Europe is the upcoming EU Medical Device Regulation (MDR). Is there anything that developers should consider when getting ready for MDR?

Bijan Elahi: Yes. MDR really created a ground shift for the medical device manufacturer. It caused a lot of change, and it’s more of a quality regulation. Some of the biggest changes with respect to risk management are the requirement to submit an annual Periodic Safety Update Report (PSUR). The PSUR is for Class II, and above medical devices. Another requirement is Post-Market Surveillance Reports (PMSR) for Class I devices. There will also be more emphasis placed on post-market clinical follows ups. The regulators expect you to continue to follow up your product and to see how it is clinically performing.

MDR puts more emphasis on post-market surveillance plans. You’ll need a plan ahead of time for surveilling your medical device and how it performs in the field. You’ll also need to identify and declare the lifetime of the medical device and provide a rationale. Article 88 in the MDR also requires trending, which will result in more reporting required by the manufacturer. If an adverse event hasn’t happened yet, but looks like it’s going to happen, then you have to report that too.

Jama Software: Interesting. So, you need to anticipate risks before something happens and there will be more documentation required?

Bijan Elahi: Yes. Before, we had vigilance reporting. Which means something bad has already happened, and you had to report it to the governmental agencies in Europe. Now in addition to vigilance, you have to predict if something bad is going to happen and report that as well.

Jama Software: Do you foresee any changes to risk management or requirements management being impacted by MDR?

Bijan Elahi: Good requirements management is just so smart to do for better and more efficient product development. I use it in risk management as well.

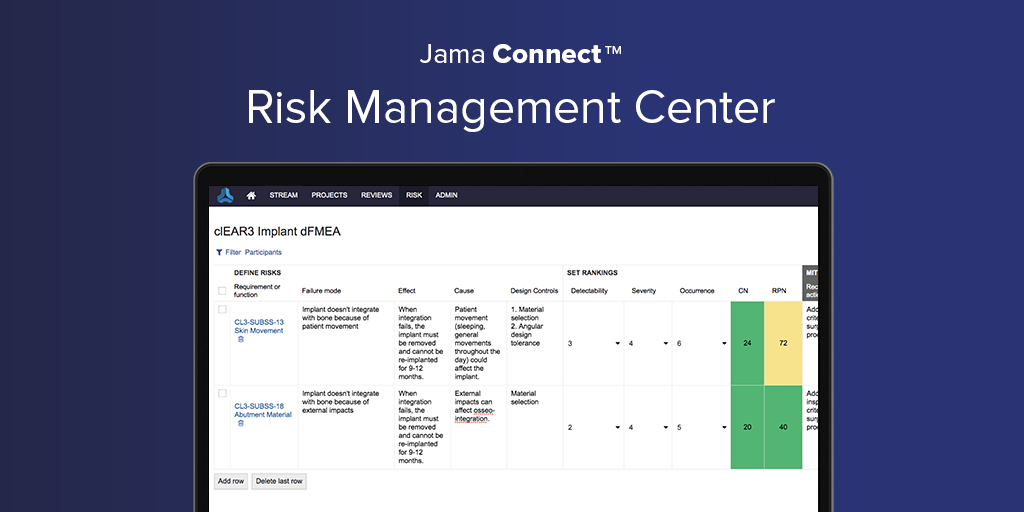

Basically, I treat hazards, risk controls, and safety requirements all as elements in the requirements management system. So, they’re all connected and traced. Traceability is another thing that is really emphasized in ISO 14971. It is so easy to do traceability with a requirements management solution like Jama software and, so hard to do it manually.

If you try to do it by manually, e.g., with an Excel spreadsheet, it’s so easy to lose traceability and have errors. It’s also hard to maintain. Anybody who has done traceability analysis knows how much work it is and how hard it is to maintain it because designs are dynamic. Things change all the time. Anytime you make a change, you could break your traceability. This is one thing that I always advise my students and my clients, to use a tool like Jama Connect.

Learn more about how Jama Connect™ helps medical device developers streamline and speed up the development process while reducing risk.

Jama Software: Are there any specific best practices or any highlights that you can address in regard to risk and requirements management together? In regard to the discipline of combining those two and how they can help product development and launching products.

Bijan Elahi: Yes, I am a strong believer that risk-management and requirements-management are better together. For example, safety requirements: How do you know which requirements are safety requirements? A safety requirement is that which is linked to a risk control. As risk controls themselves are elements in the database, if you link some of your requirements to those risk controls then you can tag those requirements as safety requirements.

Sometimes when you are audited, an auditor asks you, “What are your safety requirements?” With the explanation that I just gave, it is very easy to run a query with a solution like Jama Connect for all of the requirements that are tagged as safety and get a list of them. Very easy to do! Without a tool, it’s not so easy to answer that question.

Another example is connecting Failure Modes and Effects Analysis (FMEA) analysis to your risk management. The tool can help manage the connections of the causes and effects that lead to hazards. Again, those causal factors themselves could be elements in a database which are linked together and that creates what’s called a sequence of events, which explains how a hazard can manifest itself. By creating this chain of events, you can connect the hazard to the hazardous situation, and subsequently to the harms. You can do a quantitative computation of risk, if you follow this methodology.

Jama Software: What are some common mistakes that you’re seeing medical device developers make in their risk management process?

Bijan Elahi: The first mistake that comes to mind is actually just an approach that is suboptimal. One of the things that many device manufacturers do when it comes to assignment of severity of harm is assign just one classification to it. For example, if you are infected, they would ask, “What’s the severity of the infection?” And they would assign a severity classification like serious or critical. These are key words that I’m using, by the way.

The thing is that a harm doesn’t create just one kind of outcome, but multiple outcomes. For example, an infection could cause anything from just a little bit of a fever, to organ failure, to even death. So, it’s not best practice to assign only one severity class to a harm. It’s best to assign a spectrum of severity classes to harms.

Jama Software: As we enter a new decade and medical devices are becoming more complex and more embedded in our everyday lives, how do you think risk management might change?

Bijan Elahi: Well, I think risk management is going to become more and more important. Especially with the introduction of EU MDR. EU MDR puts more emphasis on risk management. I see a lot more ‘risk-based’ language everywhere. Decisions need to be risk-based. That applies to all kinds of decisions, including design changes and verification testing. If you’re going to make ‘risk-based’ decisions, you need to know what risk is. And where you get risk information: is from risk management. Risk management is a progressively more prominent endeavor in medical device development.

Developing medical devices in Europe? Join us on February 21 in Belfast, UK for our half-day seminar, “Risk Management for Medical Devices: The Expectations of ISO 14971.”