Automotive companies are under relentless pressure to innovate while ensuring they design and build functionally safe vehicles. Consumers expect more from the driving experience, leading to more electronic systems within product development. With the upsurge in complex electronic components like advanced driver-assistance systems (ADAS), meeting functional safety standards becomes even more critical.

We recently held a webinar, “From ADAS to Connected Systems, How to Accelerate Innovation in Automotive Development with Requirements Management?,” where we explored the common challenges that automotive developers face, and how to implement best practices aligned to functional safety standards.

Some of the key topics that were covered included:

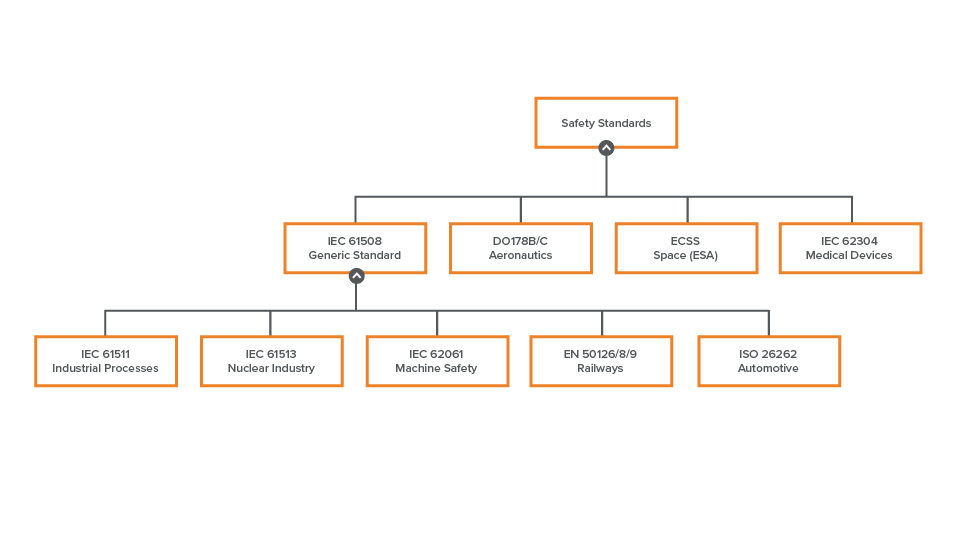

- Aligning how you work with best practices to meet functional safety standards

- Integrating functional safety with normal product development

- Using Jama Connect™ to align your product development processes with relevant parts of governing regulations and standards ISO 26262:2018 and ASPICE

This was a great webinar, and we don’t want you to miss out on the content! Below you can find a recording of the webinar, and an abbreviated transcript.

From ADAS to Connected Systems, How to Accelerate Innovation in Automotive Development with Requirements Management?

Adrian Rolufs: In today’s automotive development landscape, there’s an increase in focus on mobility services, connectivity between vehicles and other systems, higher focus on safety and more systems that are involved in safety and then as well as the electronic vehicle and the autonomous vehicle technical challenges that are being worked on. This has really changed the landscape quite significantly for companies operating in the space. We’re seeing vehicles that last longer that need to be reliable over a longer period of time. We’re seeing more regulations taking into effect that companies need to consider and there’s a lot more electronic and software systems being integrated into vehicles.

This is really having a big impact on automotive development, and there are a couple major factors that we see. One is that existing vehicle companies and suppliers are starting new teams to work on these challenges and we also see a lot of new companies coming into the automotive space. This is where Jama Connect comes in. We have put together a solution for these new teams and new companies that are working in the automotive space to help them get going quickly. A lot of these teams have a common need which is to develop technology quickly, get to market quickly while still being compliant with the safety standards and following best practices.

RELATED: Watch a demonstration of the Jama Connect for Automotive Solution

A big part of that is using a requirements management tool and having well defined requirements managing process. So, when an automotive customer buys Jama Connect for Automotive, this comes along with a process and documentation of that process for how to use the tool in a way that’s compliant with both ISO 26262 as well as Automotive SPCE which are the most common standards that companies are following in this space. We find that a lot of companies don’t have the time to set these processes up from scratch. They would prefer to leverage known practices that we can provide.

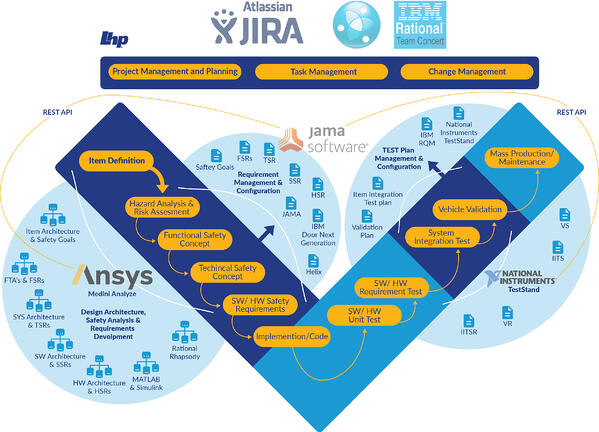

So, what does this solution look like? We first start by clarifying the scope of what Jama Connect is best used for in this space. So, there are elements of meeting ISO 26262 as well as Automotive SPICE that Jama Connect is ideally suited for and there’s other elements of those standards that don’t really apply to a tool like Jama Connect.

We provide recommended procedures for how to use Jama Connect in this framework and to meet these standards and we provide a justification for those processes linking back to the specific elements of the standards that companies must follow. And then we also provide detailed activities that are best performed in Jama Connect. And finally, we provide export templates so that all the work that you do in Jama Connect can be exported into documents for long term archival and for audit purposes.

Jama Connect for Automotive is primarily focused on requirements management, hazard and risk analysis, and test management, and the traceability between those. Jama Connect is a product that focuses on meeting those needs that customers have and the automotive solution provides the guidance for how to do that work in a way that’s compliant with automotive standards. We provide an out of the box configuration of the tool. Since Jama Connect is a highly configurable too, there are many different ways to set up the tool but this solution provides a framework that’s designed specifically to meet the industry standards for automotive in a way that makes the best use of the functionality of Jama Connect.

We also provide a process documentation to provide you guidance on how to do the work in the tool, export templates to allow you to export your documents, a Functional Safety Kit so that you can help with qualifying the software tool. We also have the ability to provide you with a data exchange for exchanging requirements in a ReqIF format between suppliers and other companies.

And finally, Jama Connect for Automotive includes consulting and training services from our Professional Services group so that your teams can learn the tool quickly and efficiently and any questions can be answered. It’s also possible during that engagement to customize the framework. The framework is offered as a starting point but a lot of customers choose to customize it to their specific business needs and our consultants will help with that.

Today we’re excited to

Today we’re excited to