How Jama Connect® Supports Trade Compliance for Vehicle Connectivity Systems

In this short demo, industry expert Fabian Koark walks through how Jama Connect helps organizations meet evolving trade compliance regulations — specifically the new 2025 update to U.S. Federal Regulation 15, targeting vehicle connectivity systems.

Learn how to classify architectural elements by trade restriction, integrate vendor data, and generate a Declaration of Conformity report – available in the latest Jama Connect for Automotive framework – directly within your existing requirements review workflows. See how Jama Connect’s dashboards, reporting, and structured data model simplify compliance tracking and streamline documentation for import/export controls.

Watch the demo to see how Jama Connect enables due diligence, traceability, and regulatory readiness in one connected platform.

VIDEO TRANSCRIPT

Fabian Koark: My name is Fabian, Fabian Koark. At the beginning of 2025, I published a discussion on my consulting service website, called consulting.com, about trade compliance and a new regulation for vehicle connectivity systems and then Jama Software and the colleagues from Jama Software approached me and asked the question, what to do in a requirements management environment to support trade compliance? And this is what this little webinar is about. We have very different import and export restrictions in the technology field. Some things are restricted for export and regulated by a critical material list, and others are restricted for import.

And in 2025, the Bureau of Industry and Security (BIS) published an update of the Federal Regulation 15 in part 791 Subpart D, that is specifically targeted towards vehicle connectivity system. And Lael Brianard summarizes pretty much this rule was established to really prevent, prohibit, in this case, Chinese and Russian adversaries to bring in software and hardware into connected vehicle on North American roads to make sure the customers are protected and the public is protected. But what to do now in our software and hardware engineering surrounding? Do we need a specific change to our hardware and software bill of material? For this context, in regulation was decided after a long review discussion that there will be no requirement for a specific format of a hardware software bill of material, but there will be, there is the requirement of a thorough due diligence that also delivers a Declaration of Conformity.

So everybody who imports part of their software and hardware for the connectivity system will have to show that due diligence was performed and has to deliver a Declaration of Conformity. So let’s see how the new release in Jama Connect is able to support this. A few things, as I mentioned before, there are the new regulation, import regulation for vehicle connectivity systems is just one, but there are other regulations. And so when we have a software and hardware development surrounding, and we have different types of classifications probably in our project, certain elements are unrestricted. Then we have a few elements that are not classified yet where it’s really unknown. We have things that are import restricted, for example, for this regulation, for vehicle connectivity systems, but we also have elements that are export restricted.

RELATED: Buyer’s Guide: Selecting a Requirements Management and Traceability Solution for Automotive

Koark: So the moment when we produce and release the product, we have to make sure that when we export it, it will be restricted to be exported to certain countries or when we export it, it has to be delivered with certain declarations and documentation. But how to get to this classification and how to get to a Declaration of Conformity, I want to show you that in a second. But first things first. If I want to classify something in Jama Connect and I want to, for example, have the classification of a trade restriction, then easiest way is I go into admin, I go into my pick lists and say, okay, I classify, everything is classified as a pick list in Jama Connect, like safety or security level and integrity level. And in this case, we introduced in the standard project in Jama Connect, the element and the pick list of a trade classification here with our different classification, general import restriction according to CBP or the export restriction by the critical material components list.

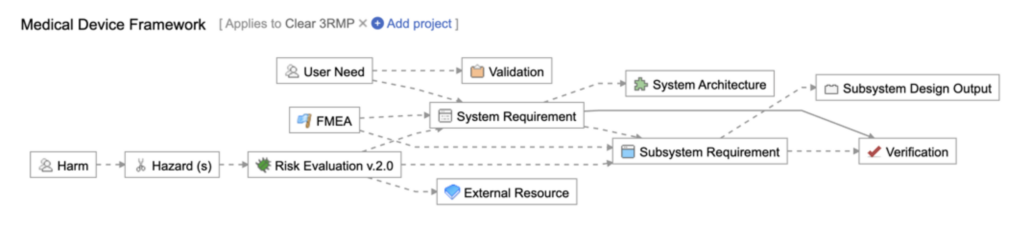

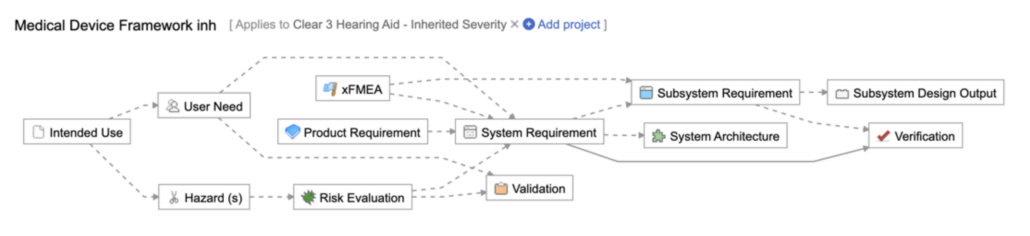

Then we take that and said, okay, where do we want to classify it? It depends on your approach. In our approach we really focused on the architectural elements. The architectural elements, no matter if it’s hardware or software, have to be classified. So we added the trade classification, but also other information like the vendor name and the vendor country to the architectural elements. And that allows us to, for example, then also pull this data and show the data in our dashboard.

Now, you will also recognize in your newest release of Jama Connect that in a report field you will have a new report called the Declaration of Conformity. What is the Declaration of Conformity? The Declaration of Conformity report is based on an existing review. That means we decided not to establish a new completely separate process. We said, okay, there is a review. There’s a verification process established in every engineering organization, and at one point in time review approval and peer reviews have to be done. So let’s use that existing process to also deliver the Declaration of Conformity. Means this will pick up an existing review and the content of it in a very specific format, and I will show you how this looks in a second. That means I have to establish a review on my specific elements, and that was already done in this particular project.

So already have a review, review. Nine in a revision, four existing, and we can go into that and take a look what we see here. So it is different elements in this regard and we already see that, we also see here the trade classification in our review view, and we see how certain things are classified. Now, once I get to, for example, a communication element like here, a transceiver module, I see this was classified with our regulation of focus today with a vehicle connectivity system, specific import restriction, and we have additional information for who’s the vendor and what’s the vendor country. And important here is as we are focusing on the elements, we also know that behavior is decided by the design specification, by the requirements that are connected to a specific element. And that’s why we can also see the different connected and specifying elements in our Jama Connect here and I can go one step deeper and then see what is actually specified here on the communication protocol.

RELATED: Traceable Agile™ – Speed AND Quality Are Possible for Software Factories in Safety-critical Industries

Koark: So I have everything in one. Now how do I now get the Declaration of Conformity? That’s exactly what I do. I run my report and then go to the Declaration of Conformity. I know I want to have my Declaration of Conformity based on the review nine in the revision four, and I want to have a Word format because I want to maybe integrate the content into a bigger report and then I can run the report. How does this report look when it comes out of the system? It identifies who the different reviewer and approver were, what are the review comments? But also then really show the information that we already had in our review. We see this is a classified element and we have the vendor information.

Furthermore, what is also important on the specification side, when we really go one level deeper, not on the element, but on the requirement we see who recreated a requirement that is related to that and when was it last modified. And that overall gives us a great baseline for Declaration of Conformity to then report to the authorities, but also to really have a review, internal review and know where things are coming from in our software and hardware development. With that, we have kind of the document layer, we have the specification and elements layer, and we have the dashboards. And I think this will bring the industry in a good spot to track compliance regarding trade restrictions. And that’s all we want to show today. If you have any questions, if you need any help, you want to tune and change your Declaration of Conformity, the support team of Jama Connect is always available. And I hope you enjoy this new feature.

![[Webinar Recap] Navigating AI Safety with ISO 8800: Requirements Management Best Practices [Webinar Recap] Navigating AI Safety with ISO 8800: Requirements Management Best Practices](https://www.jamasoftware.com/media/2025/04/Navigating-AI-Safety-with-ISO-8800.png)