In a recent webinar Michael Jastram, Senior Solutions Architect at Jama Software and Francois Xavier Dormoy, Senior Product Manager at Ansys discuss how you can bridge these gaps by integrating a product development platform, such as Jama Connect, together with a model-based embedded software tool, such as Ansys SCADE. From high-level requirements to verification and validation (V&V) activities to implementation, this allows you to share a single source of truth among the stakeholders and facilitate alignment across teams.

Below you’ll find an abbreviated transcript and the full webinar recording.

Bridging the Gaps in Safety-Critical Product Development

Michael Jastrom: In case you’ve never heard of Jama Software, Jama Connect is a solution for product development. Product development includes, of course, capturing the requirements, requirements management but also activities like test and quality management, which gives you end to end traceability. Also, risk and hazard analysis because a lot of our customers are using Jama Connect for functional safety-critical work the same way that

Ansys SCADE is being used. Jama Connect is a platform that achieves these things by providing you with key capabilities, like traceability, collaboration, reuse, and many others. I don’t want to go here into detail. In a minute, Francois and I will give you a live demonstration so that you can actually see how all this plays out in practice.

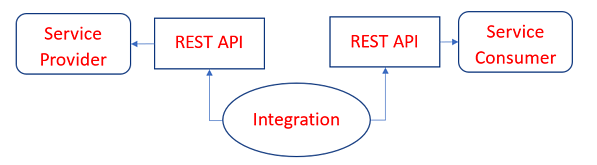

One thing that is very important that I would like to point out is that Jama Connect is an open platform. It is very easy to seamlessly integrate it with other tools. We see Jama Connect as the best of class solution. For this part of your development you want to use best of class and so do you want for others. That’s why you’re using SCADE, I assume. We ensure that you have a seamless integration.

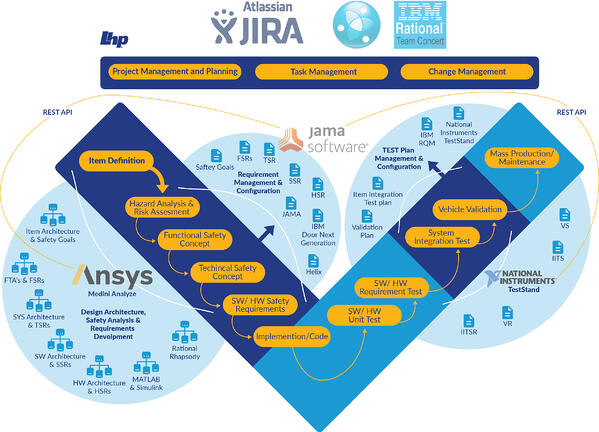

Before I give you a tour of the solution, let’s look at the problem with respect to product development today. In product development, you typically follow the V-model if you have to do with functional safety critical systems. This has been practiced since the ’60s very successfully. There’s just one problem with it. The V-model in systems engineering tends to be slow. By the time you define your concept of operations, you went all the way down to implementation there. By the time you can do the verification and validation activities of the top level, a lot of time passed. There’s a lot of interest these days in HM methodologies. One question that we often hear is how do you apply HM methods in the context of functional safety critical work and systems engineering. The answer to that we call continuous engineering.

This is how it works and where Jama Connect applies. Jama Connect basically covers the top two thirds of the V-model by providing you with a platform for modern requirements management that gives you cross functional collaboration, which allows you to easily exchange information, capture decision, conduct reviews of electronic signatures, and so forth.

At some point, you reach the point where the scope of Jama Connect ends. That’s where something like Ansys SCADE comes in. We provide you with real time and seamless traceability across two boundaries so that you have end to end traceability with best of class solutions. On the top right here, this is again where Jama Connect comes in. Jama Connect also supports you with test management activities so that you have end to end traceability from your requirements all the way to your test cases and test results. Jama Connect doesn’t end there because Jama Connect provides you with reuse capabilities that allows you to build the next version by using branching and merging of variant management so that you can easily manage multiple variants and take advantage of the good work that you already did.

The next question is how do you actually apply that in practice? This requires a paradigm shift. This is visualized on the left-hand side here by depicting the traditional systems engineering approach, which tends to be document based, which you can see here with example outlines from the corresponding RS standard. Now, we haven’t worked with documents in systems engineering for a while. There are tools around for requirements management. Yet, if you look at all the generation of requirements tools, that still has a very strong document feel to it. In Jama Connect we really switch away from that and go to an item-based mindset where you have fine grade traceability. Obviously, to really understand on a fine grade level what the impact of change is, where you have gaps in your coverage, and so forth.

Here you see you simply find relationship model that shows you how you can connect to various items. For example, you can have themes and epics, which are terms from the ancient world, but still mixed it up with things like product concept and system architecture, which are more traditional systems engineering. If we have a look at that, then you get something like this. This relationship diagram has been actually taken directly from Jama Connect so you can flexibly adapt it there. The arrows indicate the traceability capabilities. For example, you that epics and user stories are connected. Jama Connect will tell you if you have a gap between your epic and your user story. You can find gaps in your coverage. Jama Connect helps you with impact and change management. If you change the epic, then all the connected user stories and validation test cases will be marked as suspect. There are a number of other features, roles, workflows, templates. A number of capabilities that really allow you to have repeat iterations following the traditional systems engineering process but with an agile mindset. We have customers from many different industries. Just to provide you with one example, one of our customers from the avionics industry used Jama Connect in a lot of areas. Just to pick up one metric, they managed to increase the speed of resolving issues by 30% by using what Jama Connect provides you with.

RELATED: Watch a demonstration of the Jama Connect for Automotive Solution

Francois Xavier Dormoy: Yes, the topic is how we can make this synchronization and how we can integrate both SCADE models, and these requirements, and these traceability. In fact, we have in SCADE and in all SCADE tools, we have a gateway. A gateway to requirement management tool, like Jama Connect. For instance, in Jama Connect, of course, you will be able to create requirements, to manage requirements, manage traceability links. You can create links. You can see all the traceability. You can perform your impact analysis. You can generate matrices, etc. All these, of course, will be done in Jama Connect and you will use SCADE for design, for the architecture, for the testing, etc.

What we allow in this gateway is for people designing to have a look at the requirements. We have a way to import in SCADE requirements and we have a way in SCADE to create links between SCADE elements, SCADE artifacts, and any requirements. These links will not be stored in SCADE. They will be stored in Jama Connect. We have the six portraiture in order to export back to Jama SCADE artifacts together with traceability.