Tailor Plans and Templates in Jama Connect®: The Value of Having Process and Tools in a Single Place

There are dozens of regulations, best practice frameworks, and corporate governance standards that all describe the value of documenting the processes used to design and develop systems upfront before development begins and suggest that evidence be collected to demonstrate that the documented processes were followed. The end goal is to effectuate process improvement and develop behaviors that decrease risks in service, product, and software development. To the engineers in the trenches doing the work, it can be daunting to keep up with following the right process, especially in aviation. Observations I have after working in the industry for over 25 years is that:

- Engineers have difficulty translating what is in the process document to how to perform their work every day.

- Engineers do not have the time to go searching for the latest process documents.

- Engineers are not certain the content in process documents are enough or correct to satisfy critical audits.

- Engineers wish that the process of documentation and evidence demonstration was captured automatically in the tools they use day to day.

- Engineering managers wish that more time could be given for training in state-of-the art engineering techniques rather than process training.

Related: ARP4761A Introduction for Engineers and Managers

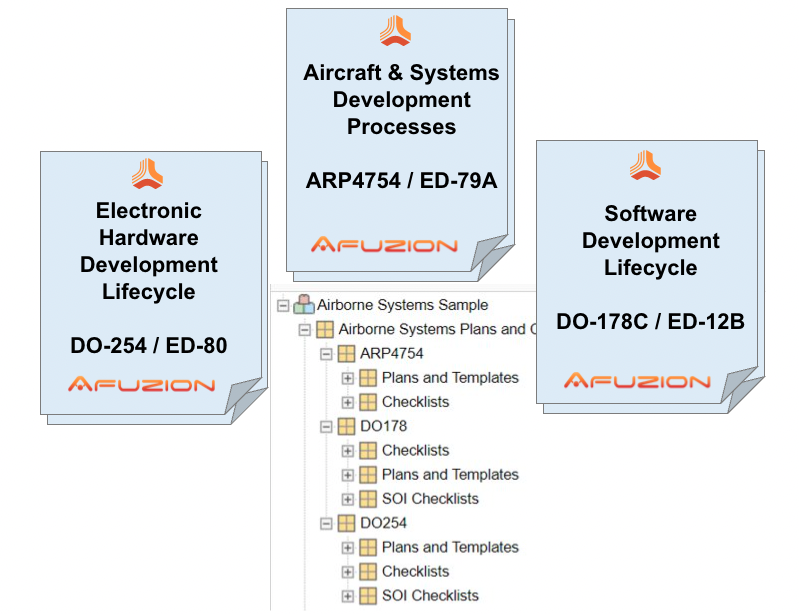

EASA and the FAA point towards industry standards which all call for a plethora of documentation that needs to be created to support the objectives. DO-178C (Airborne software), DO-254 (Airborne firmware/hardware), and ARP4754A (Aircraft/Systems) also require reviews, audits, and proof thereof. Some of the best “proof” is detailed and complete checklists covering the primary lifecycle activities and their generated artifacts.

Jama Connect® can provide engineers with a single place to author and read documentation without having to leave the requirements tool in which they are working and look in a file share. The process guidance need not be static but should also assist engineers to follow the process while performing their work. The Jama Connect workflow engine and process documentation can be tailored together to take advantage of streamlining the work that engineers do and assist in the automation of evidence collection and reporting.

The built-in Review Center in Jama Connect can also assist with review of process documentation in each stage of involvement (SOI) in addition to review of requirements, verifications, and risks. By taking an iterative and collaborative approach to reviewing lifecycle data in real-time, Review Center improves stakeholder alignment, reduces lengthy review cycles, and eases the path to compliance. Traditional review processes often stifle collaboration resulting in misalignment, long review cycles, versioning issues, and an abundance of unnecessary meetings. Having a centralized place to manage and collaborate on reviews eases keeping track of the findings and observations, making reviews more efficient and scalable.

Related: Afuzion Plans and Checklists for DO-178C, DO-254, and ARP4754A

AFuzion’s Aviation Compliance Templates and Checklists are now integrated within Jama Connect™. This proprietary content is used by 17,000 engineers worldwide in 25 countries for most certification agencies including FAA, EASA, NASA, ESA, TC, CAAC, CASA, DASA, STM, INTA, RNZAF, MOD, US ARMY, US Air Force and many more. AFuzion has spent 200 person-years of expert aviation engineering time to develop these full templates; this means you begin effective aviation development/certification work immediately instead of expending 10-16 person months developing inferior plans/standards/checklists on your own.

Using DO-178C and DO-254 templates for Plans, Standards, and Checklists ensures that you have an appropriate framework for successfully developing and certifying your system. These templates and checklists can also help in getting organizations to the goal of higher SEI CMM/CMMI ratings (preferably Level 3 – 4+). Usage of AFuzion’s process templates and checklists are intended to maximize the probability of project success and quality by:

• Reducing costs by using pre-built material from the most well-known industry experts instead of spending 2-3 person years typically necessary to develop these internally

• Eliminating tools silos by keeping your Process documents in line with your requirements data

• Enabling better communication of process requirements to your engineering teams